Blow mould manufacturing Services in India

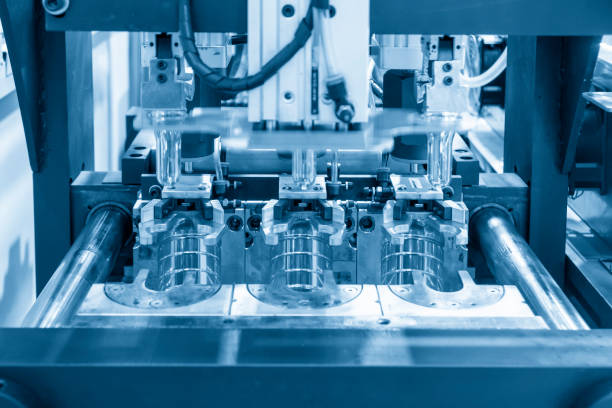

Blow mould manufacturing is a critical process in the plastics industry, enabling the mass production of hollow plastic products such as bottles, containers, tanks, and toys. At My Design Minds, we offer custom blow mould manufacturing services in India, tailored for both local and global clients looking to outsource high-quality solutions. This method is renowned for its efficiency, versatility, and ability to produce complex shapes at high volumes.

What is Blow Moulding?

Blow moulding manufacturing is a process by which hollow plastic parts are formed. The process involves inflating a heated plastic tube, known as a parison or preform, inside a mould cavity so that it takes the shape of the mould. Once cooled, the mould opens, and the finished product is ejected.

Types of Blow Mould Manufacturing

There are several types of blow moulding process used depending on the product and material.

1.Extrusion Blow Moulding (EBM)

Process: A molten tube of plastic is extruded vertically between two halves of a mould. The mould closes, pinching the at the bottom, and air is blown in to inflate the plastic against the mould walls. After cooling, the mould opens and the part is ejected.

Applications: Bottles, automotive ducts, large containers, and toys.

Advantages: Suitable for large and complex shapes, handles can be incorporated.

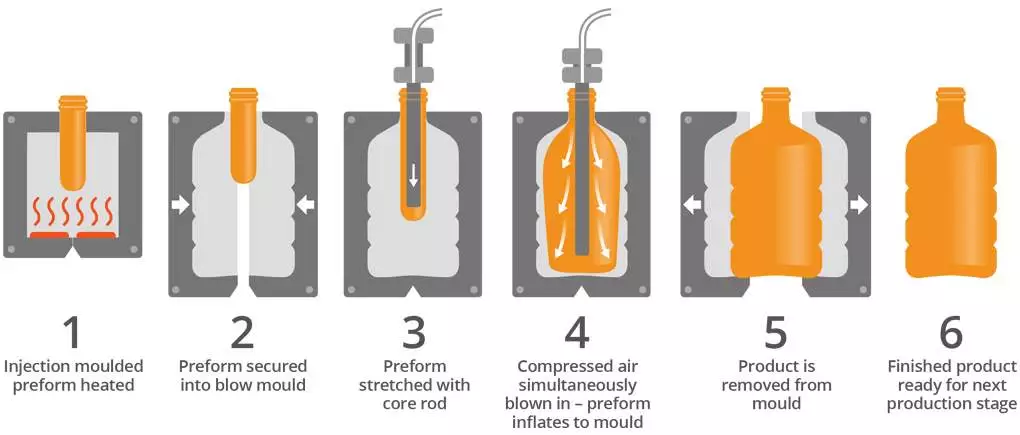

2.Injection Blow Moulding (IBM)

Process: A preform is injection-moulded onto a core pin, then transferred to a blow mould. Air is injected, inflating the preform to the shape of the mould. The part is then cooled and ejected.

Applications: We are among the trusted blow mould manufacturers in Delhi NCR, serving various industries with advanced tooling and fast turnaround times. Small bottles (e.g., for pharmaceuticals, cosmetics), jars.

Advantages: High precision, excellent surface finish, suitable for small and medium-sized products.

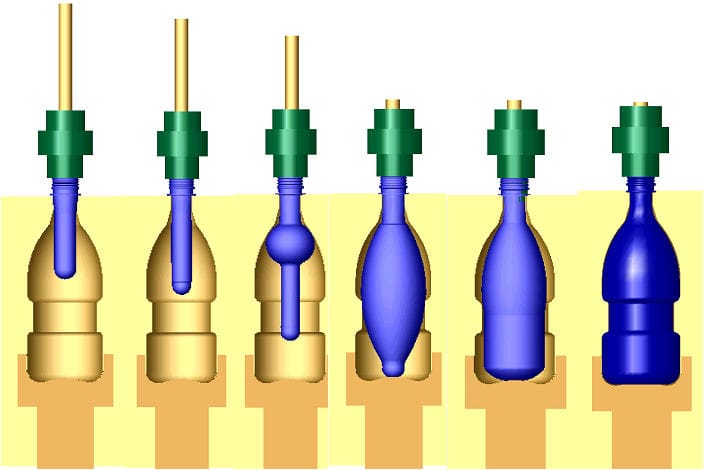

3.Stretch Blow Moulding (SBM)

Process: Used primarily for PET bottles. A preform is first injection-moulded, then reheated, stretched lengthwise, and blown into the final shape within a mould.

Applications: Carbonated drink bottles, water bottles.

Advantages: High strength-to-weight ratio, clarity, and uniform wall thickness.

Materials Used

We also specialize in high-precision blow mould manufacturing for automotive parts, ensuring our components meet stringent tolerances and performance standards required in global automotive supply chains. The choice of plastic blow moulding materials depends on the product’s application and performance requirements

Polyethylene (PE): Widely used for bottles and containers due to its flexibility and chemical resistance.

Polyethylene Terephthalate (PET): Preferred for beverage bottles for its clarity and strength.

Polypropylene (PP): Used for containers requiring higher temperature resistance.

Polyvinyl Chloride (PVC): Used for certain bottles and containers, though less common due to environmental concerns.

Blow Mould Design Considerations and manufacturing process

In My Design Minds, the quality of the final product heavily depends on the design and manufacturing of the blow mould itself.

Design Considerations:

Blow mould design plays a vital role in ensuring product consistency and efficiency during production

Material Selection: Moulds are typically made from hardened steel or aluminium for durability and thermal conductivity.

Cavity Design: The mould must allow for even wall thickness and accommodate any required features (threads, handles, etc.).

Cooling System: Efficient cooling channels are critical for rapid cycle times and dimensional stability.

Venting: Proper venting prevents air trapping and ensures complete forming of the product.

Manufacturing Process:

Design: CAD software is used to design the mould based on the product specifications.

Machining: CNC machines, EDM (Electrical Discharge Machining), and other precision tools are used to create the mould cavity and core.

Polishing and Assembly: The mould is polished for surface finish and assembled with all necessary components (cooling lines, ejector pins, etc.).

Testing and Adjustment: Trial runs are conducted to check for defects, and adjustments are made as needed.

Recent Advancements

Automation: Robotics and automated systems have improved efficiency and consistency.

Simulation Software: Advanced mould flow analysis helps optimize design before manufacturing.

Sustainable Materials: Biodegradable and recycled plastics are increasingly being used.

3D Printing: Additive manufacturing is being explored for rapid prototyping and even direct mould making.

Why Outsource Blow Moulding to India?

India has become a preferred hub for plastic blow moulding companies outsourcing to India due to its combination of skilled workforce, affordable tooling, and cutting-edge manufacturing technology. My Design Minds bridges global demands with local expertise, delivering scalable solutions with cost-effectiveness and precision.

Conclusion

Blow mould manufacturing is a cornerstone of the plastics industry, offering a cost-effective and efficient way to produce hollow plastic products. With ongoing advancements in materials, design, and automation, the process continues to evolve, meeting the demands of various industries while addressing environmental concerns. Whether for everyday bottles or specialized industrial components, blow moulding remains an indispensable technology in modern manufacturing.