In My Design Minds, Injection mould manufacturing is the cornerstone of modern industrial manufacturing, enabling the mass production of complex, high-precision plastic parts for industries that range from automotive and electronics, medical equipment, and consumer products. The injection mould manufacturing involves advanced design, premium materials, and precision machining to create moulds that can withstand high pressure and repeated use. Following is a comprehensive review of the injection mould production process, phases, materials, design considerations, and latest advances.

This article provides a complete overview of the industrial injection mould design services in India, detailing the design process, machining techniques, material choices, and recent innovations used in plastic injection mould tooling.

Steps in Injection Mould Manufacturing

1. Product Design and Mould Specification

Product Analysis: It begins with detailed analysis of the part to be produced, considering the geometry, material, tolerances, and application.

Mould Design: CAD(Computer-Aided Design) software is utilized to design the mould, specifying the number of cavities, gating system, cooling channels, ejector system, and special requirements.Our expert engineers follow best practices in injection mould design services in Delhi NCR to deliver optimal performance.

2. Material Selection

Mould Materials: Standard choices are heat-treated tool steels (e.g., P20, H13, S7), corrosion-resistant stainless steels, and sometimes aluminium for prototype or short-run moulds.

Selection Criteria: Criteria include anticipated volume of production, required surface finish, degree of complexity, and expense. Our low-cost injection mould manufacturing in India solutions are ideal for start-ups and SMEs worldwide.

3. Mould Manufacturing Process

- Machining

CNC Milling: Computer-controlled CNC (Computer Numerical Control) milling machines machine the overall shape of the mould cavity and the core.

EDM (Electrical Discharge Machining): For making intricate shapes, deep pockets, and fine details that are difficult to achieve with standard milling.

Drilling: For cooling channels, ejector pin holes, etc. - Temperature Treatment

Hardening: Mould components are heat-treated to achieve the required hardness and wear resistance.

Tempering: Eliminates brittleness without sacrificing strength.

- Finishing

Polishing: Gives the desired surface finish, ranging from high-gloss to textured.

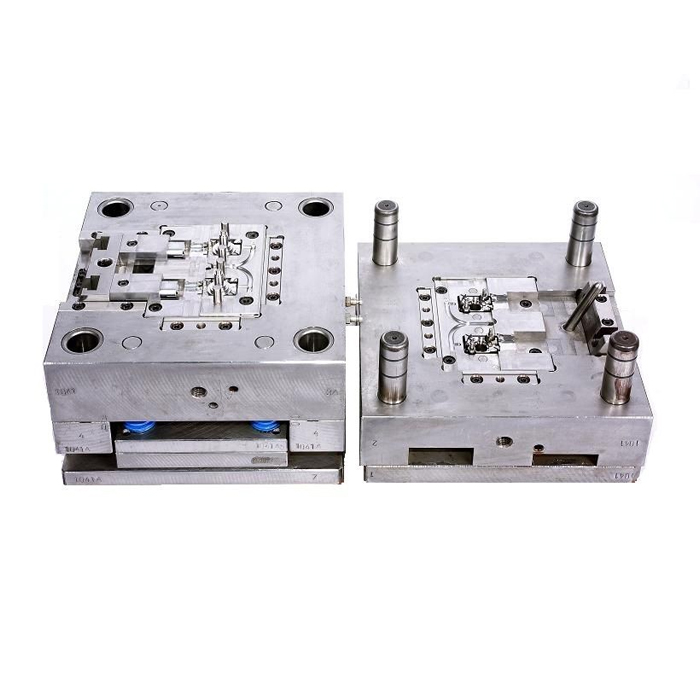

Assembly: All the elements of the mould, including cores, cavities, runners, gates, ejector pins, and cooling lines, are properly assembled. - Testing and Validation

Trial Runs: The mould is fitted in an injection moulding machine, and trial runs are conducted to check for defects, size, and cycle time.

Modification: Modifications are made as necessary before placing the mould into production.

Key Design Considerations

Parting Line: Where the two mould halves meet, having an effect on appearance and function.

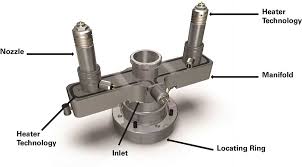

Gating System: Controls how molten plastic is fed into the cavity, affecting flow, fill, and quality.

Cooling System: Good cooling channels reduce cycle time and prevent warping.

Ejection System: Ejects part gently without destruction.

Venting: Avoids burn marks and insufficient filling by allowing trapped air to escape.

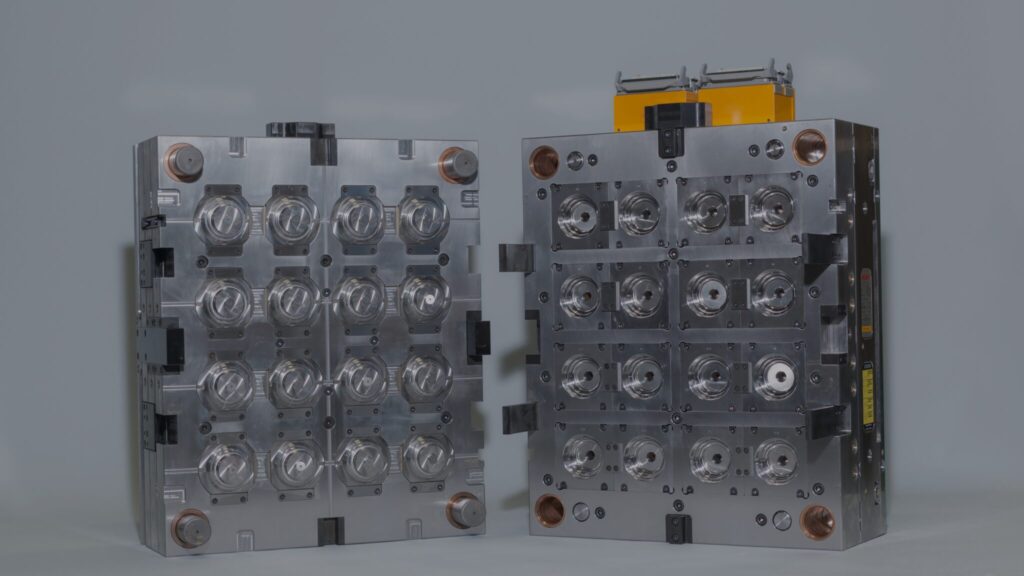

Injection Moulds Categories

|

Single-Cavity Moulds: Produce one part per shot; used for low to medium levels or large parts. |

|

|

Multi-Cavity Moulds: Produce many similar parts per shot, increase productivity for high-volume production. |

|

|

Hot Runner Moulds: Use heated channels to keep the molten plastic, reduce waste and cycle time. |

|

|

Cold Runner Moulds: Simpler design but produce more scrap, perfect for some applications. |

|

Latest advanced injection mould manufacturing techniques for industrial applications involves

Conformal Cooling: 3D moulded cooling channels that encircle the mould, increasing part quality and cooling.

Simulation Software: Advanced software models flow, cooling, and warpage, reducing trial-and-error.

Automation: Automated parts handling and robotic inspection increase throughput and consistency.

Sustainable Practices: Recycling of plastics, energy-efficient equipment, and moulds constructed to last.

Challenges in Injection Mould Manufacturing

High Initial Cost: Tooling is expensive, but offset by high-volume output.

Complexity: Mould design and production of complex parts require expertise and high-tech machinery.

Maintenance: Regular maintenance is essential in guaranteeing durability and consistency of quality.

At My Design Minds, we combine engineering excellence with cost-effective execution to deliver industry-leading injection mould manufacturing services in Delhi NCR. Our facilities are also well-equipped to serve international clients looking to outsource injection mould design to India, ensuring both high quality and competitive pricing.